Back to top

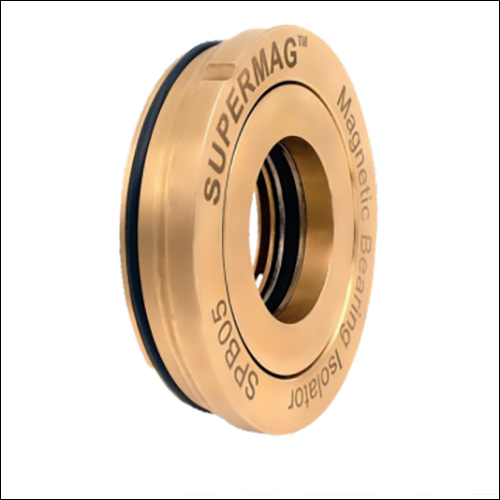

Offering a wide range of Mechanical Seals For Metallic Pumps Type 21, Ptfe Bellow With Replaceable Faces, Mechanical Seal For High Slurry Applications, Mechanical Seal For Stainless Steel Vessels, and so on.....

About Us

To make our types ZR100/D, 531/D/B, ZR200/D (Metallic Pump and Mills), and ZR300/D, Superproof Seals Engineering Pvt. Ltd. researched sealing solutions (Non-Metallic Pump). Our products like Multiple Spring Seal, Elastomer Bellow Seal, Conical Spring Seal, Reverse Balanced Seal, Metal Bellow Seal, Slurry Seal, Unbalanced Seal, etc., are excellent for use with slurries in process industries (metal pumps and side entry mills), as well as with abrasive slurries in pickling and ARP plants for the steel industry (Non-Metallic Pump).

To meet international standards and laws on emission control, our products are created under the most recent international standards, such as EN12756. We have received the TUV Austria EN ISO-9001:2008 certification, which attests to the high caliber of our Mechanical Seals. Young and energetic Mr. Zuber H. Charolia, Mr. Asif Manasiya, and Mr. Akil I. Manasiya founded our firm, M/s Super Proof Engineering Works, in 2001. Before this business, they had 12+ years of experience. Our company manufactures and exports various Industrial Mechanical Seals and is a reputable NABCB ISO and UKAS ISO certification.

After ten years of operation, we converted our status from a proprietor enterprise to a private limited company in 2011. We adopted the name M/S Super Proof Seals Engineering Pvt. Limited. Under the direction of Mr. Zuber Charolia, one of our directors, we are doing our business successfully. He put a lot of personal effort into developing, fabricating, and debugging. He gained a great deal of expertise in the mechanical sealing solutions needed in the chemical process industries throughout his time as a know-how expert.

We have a cutting-edge manufacturing facility in Maharashtra, India, outfitted with all advanced machining tools like grinding CNC machines, drilling machines, lapping machines, and lathe machines to meet various mechanical seal requirements through quality control procedures. Our products are used in chemical processes as explanation items for different sealing solutions. In addition to the Indian Subcontinent, Australia/New Zealand, the Caribbean, North Africa, East/Middle Africa, East Europe, South/West Africa, East Asia, Central America, Middle East, North Europe, South/West Europe, South America, North America, and South East Asia are some of the countries where we serve clients.

Our Quality

We prioritize quality and strive to provide our customers with high-quality products. We produce the product line under EN12756 production standards as a TUV Austria EN ISO-9001:2008 certified business. We get the materials from some reliable suppliers in China after performing quality checks on certain factors. Various operational factors are examined on our products, including:

- Durability

- Rapid environmental testing

- Exclusion of contamination

- Rusting from salt fog

- Frozen fracture

- Pump speed

- Inertia and torque

- A dry suit

- Compatibility of materials

Infrastructure We Use

We have a sizable infrastructure with all the necessary tools and equipment. We have a laborious warehouse divided into numerous areas to aid in the simple recovery of the produced materials and products. Our facility receives frequent technological upgrades. The equipment set up at our facility is:

- Drilling Machines

- Grinding Machines

- Lathe Machines

- Lapping Machines

- CNC Machines

Send Inquiry

Send Inquiry Send SMS

Send SMS